Have you ever wondered why some commercial buildings seem to weather decades of harsh winters, scorching summers, and everything Mother Nature throws their way, while others constantly battle leaks and require frequent repairs? The answer often lies hidden in plain sight, stretched across their rooftops like a protective shield that most people never think about until something goes wrong.

Picture walking through any commercial district in Bucks County and looking up at the flat-roofed warehouses, office buildings, and retail centers that form the backbone of our local economy. What you’re seeing is likely one of the most underappreciated yet critical building components: the commercial roofing system.

Among all the options available today, one material stands out as the silent workhorse that keeps businesses dry, comfortable, and operational year after year. That material is modified bitumen, and understanding why it has become the go-to choice for smart commercial property owners might just save you thousands in repairs and countless sleepless nights worrying about your building’s protection.

What Exactly Is Modified Bitumen Roofing?

When most people hear “modified bitumen,” their eyes might glaze over at what sounds like technical jargon. But the reality is much simpler and more interesting than you might expect. Think of modified bitumen as the evolution of traditional tar and gravel roofing, but with a modern upgrade that makes it significantly more durable and reliable.

Modified bitumen roofing consists of asphalt that has been enhanced with rubber or plastic polymers to create a material that combines the waterproofing properties of traditional asphalt with improved flexibility and strength. The “modified” part refers to these polymer additives that transform ordinary asphalt into something much more resilient.

The most common types of polymers used are APP (atactic polypropylene) and SBS (styrene-butadiene-styrene). While these names might sound complicated, what they do is straightforward: APP creates a material that performs exceptionally well in high heat, while SBS provides excellent flexibility in cold weather. Both types address the traditional weaknesses of standard asphalt roofing.

This roofing system typically comes in rolls that are either torched down (for APP systems) or adhered with cold adhesives or hot asphalt (for SBS systems). The result is a seamless membrane that creates an incredibly effective barrier against water infiltration.

What makes modified bitumen particularly appealing for commercial applications is its proven track record. This isn’t experimental technology; it’s been protecting commercial buildings for decades, with many installations from the 1970s and 1980s still performing well today when properly maintained.

Why Commercial Properties Love Modified Bitumen

Commercial building owners face unique challenges that residential property owners rarely encounter. The stakes are higher, the roof areas are larger, and the consequences of failure can impact not just property but business operations, employee safety, and significant financial investments.

Durability That Makes Business Sense

For commercial property owners, every roofing decision is ultimately a business decision. Modified bitumen delivers on the financial metrics that matter most. The typical lifespan of a well-installed modified bitumen roof ranges from 20 to 30 years, which means property owners can plan their capital expenditures with confidence.

This longevity isn’t just about the material itself; it’s about how the material responds to the real-world conditions commercial buildings face. Large flat roofs experience significant thermal movement as they heat up during the day and cool down at night. Traditional roofing materials can crack or separate under this constant expansion and contraction, but modified bitumen’s polymer enhancement allows it to flex without failing.

Weather Resistance Tailored to Our Climate

Changing climates present particular challenges for commercial roofing. We experience everything from heavy snow loads that can stress roof structures to intense summer heat that can cause thermal shock in roofing materials. Modified bitumen handles these extremes better than many alternatives.

During winter, the flexibility of SBS-modified systems prevents cracking when temperatures drop well below freezing. The material remains pliable even in severe cold, which means it can accommodate building movement and thermal contraction without developing leaks.

In summer heat, APP-modified systems excel by maintaining their stability even when roof surface temperatures exceed 160 degrees Fahrenheit. This heat resistance prevents the softening and flow that can occur with lesser materials.

Maintenance and Repair Advantages

One of the most practical benefits of modified bitumen for commercial properties is how maintainable it is. When repairs are needed, they can often be completed without replacing entire sections of roofing. Small punctures or tears can be patched effectively, and if larger areas need attention, new modified bitumen can be installed over the existing system in many cases.

This repairability translates to lower long-term maintenance costs and less business disruption. Instead of scheduling major roof replacements that might require temporary relocations or business interruptions, many issues can be addressed during normal business hours with minimal impact.

The Installation Process: Precision That Matters

Understanding how modified bitumen roofing is installed helps explain why it performs so well and why choosing experienced contractors like Martin Roofing & Construction makes such a difference in the final result.

Surface Preparation: The Foundation of Success

Every successful modified bitumen installation begins with thorough surface preparation. This isn’t just about having a clean surface to work on; it’s about creating the right foundation for a roofing system that needs to perform flawlessly for decades.

The existing roof deck must be structurally sound and properly sloped to ensure water drainage. Any damaged areas need repair, and the surface must be completely dry before installation begins. Proper insulation installation is also critical at this stage, as it affects both energy efficiency and the thermal performance of the roofing membrane.

Base Sheet Installation

Most modified bitumen systems start with a base sheet that provides additional protection and creates an ideal surface for the final membrane. This base sheet is typically mechanically fastened to the deck, providing wind uplift resistance and a stable foundation.

The base sheet also serves as a backup barrier. Even if the top membrane experiences damage, the base sheet provides an additional layer of protection while repairs are being planned and executed.

Membrane Application Techniques

The installation of the modified bitumen membrane itself requires both technical skill and attention to detail. There are several application methods, each with specific advantages:

- Torch Application (APP Systems): This method involves using a torch to heat the bottom of the membrane roll, causing it to adhere to the prepared surface. While this creates an excellent bond, it requires experienced technicians who understand proper heating techniques and safety protocols.

- Cold Adhesive Application (SBS Systems): This method uses specialized adhesives that don’t require heating, making it safer in many situations and allowing installation in a wider range of weather conditions.

- Hot Asphalt Application: Traditional hot asphalt can be used to adhere certain types of modified bitumen, combining time-tested installation techniques with modern materials.

Seam Sealing and Quality Control

The most critical aspect of any modified bitumen installation is ensuring that all seams are properly sealed. These overlap areas are where most failures occur if installation isn’t done correctly. Professional contractors use specialized tools and techniques to ensure complete bonding at all seams.

Quality control during installation involves continuous inspection of work as it progresses. Experienced installers check for proper adhesion, adequate overlap at seams, and correct handling around roof penetrations and detail areas.

| Installation Method | Best Climate Conditions | Installation Speed | Equipment Required | Skill Level Needed |

| Torch Application (APP) | Dry, mild temperatures | Fast once started | Torches, safety equipment | High – requires certified technicians |

| Cold Adhesive (SBS) | Wide temperature range | Moderate | Adhesive applicators, rollers | Moderate to high |

| Hot Asphalt | Cool to moderate temperatures | Fast | Hot asphalt kettles, mops | High – requires experienced crews |

| Self-Adhering | Moderate temperatures, low wind | Moderate | Basic hand tools, rollers | Moderate |

Longevity Benefits That Protect Your Investment

When commercial property owners evaluate roofing options, they’re making decisions that will impact their properties for decades. Modified bitumen’s longevity benefits go beyond just lasting a long time; they provide predictable performance that allows for better business planning and budgeting.

Predictable Aging Characteristics

Unlike some roofing materials that can fail suddenly and catastrophically, modified bitumen tends to age gradually and predictably. This means that property owners can plan for maintenance and eventual replacement rather than being surprised by emergency repairs.

The polymer modification in the asphalt helps prevent the brittleness that develops in unmodified asphalt over time. While traditional asphalt roofing might become brittle and crack after 10-15 years, properly installed modified bitumen maintains its flexibility much longer.

UV Resistance and Surface Protection

Commercial buildings often have large areas of roof surface exposed to direct sunlight throughout the day. UV radiation is one of the primary enemies of roofing materials, causing degradation that leads to cracking, brittleness, and eventual failure.

Modified bitumen systems address UV exposure through several strategies. Many systems include granulated cap sheets that reflect UV radiation and provide a protective barrier. The polymer modification itself also improves UV resistance compared to standard asphalt.

For even better performance, reflective coatings can be applied over modified bitumen systems to reduce heat buildup and further extend system life. These cool roof applications can also provide energy savings by reducing air conditioning loads.

Thermal Cycling Performance

Commercial buildings experience significant thermal cycling as they heat up during the day and cool down at night. This constant expansion and contraction puts stress on roofing systems, particularly at seams and detail areas.

Modified bitumen’s enhanced flexibility allows it to accommodate this movement without developing stress cracks. The material can expand and contract with the building while maintaining its waterproof integrity.

Why Modified Bitumen Works So Well for Commercial Applications

Commercial roofers in Hatboro and beyond are presented challenges that are quite different from those related to residential applications. Understanding these challenges helps explain why modified bitumen has become such a popular choice for business owners who need reliable, long-term performance.

Large Roof Areas and Economies of Scale

Commercial buildings typically have much larger roof areas than residential properties, which affects both installation considerations and long-term performance requirements. Modified bitumen works well for large installations because it can be applied efficiently over big areas while maintaining consistent quality.

The roll format of modified bitumen makes it practical for covering large expanses quickly. Professional crews can install significant square footage in a day when conditions are right, which helps minimize business disruption during installation.

HVAC and Equipment Integration

Commercial buildings usually have substantial HVAC equipment, satellite dishes, signs, and other equipment mounted on their roofs. Modified bitumen systems handle these penetrations well because they can be detailed around equipment bases and supports effectively.

When maintenance is needed on roof-mounted equipment, modified bitumen’s durability means that technicians can walk on the roof without causing damage, provided they use appropriate care and procedures.

Code Compliance and Insurance Considerations

Commercial properties must meet more stringent building codes and insurance requirements than residential buildings. Modified bitumen systems can be designed to meet various code requirements for fire resistance, wind uplift resistance, and energy efficiency.

Many insurance companies recognize the reliability of properly installed modified bitumen systems, which can sometimes translate to better insurance rates or fewer coverage restrictions.

Warranty and Service Life Expectations

Commercial property owners need predictability for their capital planning. Modified bitumen systems typically come with manufacturer warranties ranging from 15 to 30 years, depending on the specific system and installation requirements.

These warranties, combined with the material’s proven track record, give property owners confidence in their roofing investment and help with long-term financial planning.

Common Modified Bitumen Applications

Understanding where modified bitumen works best helps commercial property owners determine if it’s the right choice for their specific building and situation.

Warehouse and Industrial Buildings

Large warehouse and industrial buildings are ideal candidates for modified bitumen roofing. These buildings typically have relatively simple roof layouts with minimal penetrations, which allows the system to be installed efficiently and perform optimally.

The durability of modified bitumen is particularly valuable for industrial applications where roof traffic might be heavier than in office buildings. The material can withstand the occasional maintenance worker or equipment installation without sustaining damage.

Retail and Office Buildings

Office buildings and retail centers benefit from modified bitumen’s reliability and relatively quiet installation process. Unlike some roofing systems that require noisy equipment or disruptive installation procedures, modified bitumen can often be installed with minimal impact on business operations below.

The energy efficiency potential of reflective modified bitumen systems is particularly attractive for these buildings where HVAC costs represent a significant operating expense.

Educational and Healthcare Facilities

Schools, hospitals, and other institutional buildings often choose modified bitumen for its proven performance and lower lifecycle costs. These facilities need roofing systems that won’t require frequent repairs or replacement, as budget cycles and capital planning are often complex in institutional settings.

Maintenance Requirements for Long-Term Success

No roofing system performs to its full potential without appropriate maintenance, and modified bitumen is no exception. However, the maintenance requirements are generally straightforward and can prevent many problems when followed consistently.

Regular Inspection Protocols

Professional inspections should be conducted at least twice per year, typically in spring and fall. These inspections should focus on seams, detail areas around penetrations, and any areas where water might pond.

Early detection of minor issues allows for simple repairs that prevent larger problems. A small seam separation that might cost a few hundred dollars to repair could lead to thousands in damage if left unaddressed.

Drainage System Maintenance

Proper drainage is critical for any flat roofing system, and modified bitumen is no exception. Keeping drains and gutters clear of debris ensures that water doesn’t pond on the roof surface, which can accelerate wear and increase the likelihood of leaks.

Regular cleaning of drains and gutters should be part of any commercial building maintenance program, regardless of the roofing material in use.

Protective Measures

While modified bitumen is durable, it’s not indestructible. Establishing protocols for roof access can prevent unnecessary damage from foot traffic or equipment placement. Simple measures like designated walkways or equipment pads can significantly extend system life.

Cost Considerations and Value Analysis

Commercial property owners naturally want to understand the financial implications of their roofing decisions. Modified bitumen systems typically fall in the middle range of commercial roofing costs, but their value proposition extends beyond initial price.

Initial Investment vs. Lifecycle Costs

While modified bitumen might cost more initially than some alternatives, its longevity and lower maintenance requirements often make it more economical over the system’s life. Property owners should evaluate roofing options based on cost per year of service rather than just initial installation cost.

Energy Efficiency Opportunities

Reflective modified bitumen systems can provide significant energy savings in cooling-dominated climates. These savings can offset some of the initial roofing investment and continue providing value throughout the system’s life.

Repair and Maintenance Economics

The repairability of modified bitumen systems provides ongoing value by allowing property owners to address issues promptly and economically rather than deferring problems until major interventions become necessary.

Working with Professional Contractors

The performance of any roofing system depends heavily on proper installation, and modified bitumen is no exception. Working with experienced contractors like Martin Roofing & Construction ensures that the system is installed correctly and will provide the long-term performance that commercial property owners expect.

Experience with Commercial Applications

Installing modified bitumen on commercial buildings requires understanding the unique challenges these projects present. Experienced commercial roofing contractors understand scheduling requirements, safety protocols, and quality standards that apply to commercial work.

Manufacturer Relationships and Training

Professional roofing contractors maintain relationships with material manufacturers and ensure their crews receive ongoing training on proper installation techniques. This training is particularly important for modified bitumen systems where installation quality directly impacts long-term performance.

Project Management and Communication

Commercial roofing in Warminster and the surrounding areas requires careful coordination to minimize business disruption. Experienced contractors provide clear communication throughout the project and work with property owners to schedule work during optimal times.

The Martin Roofing & Construction Advantage

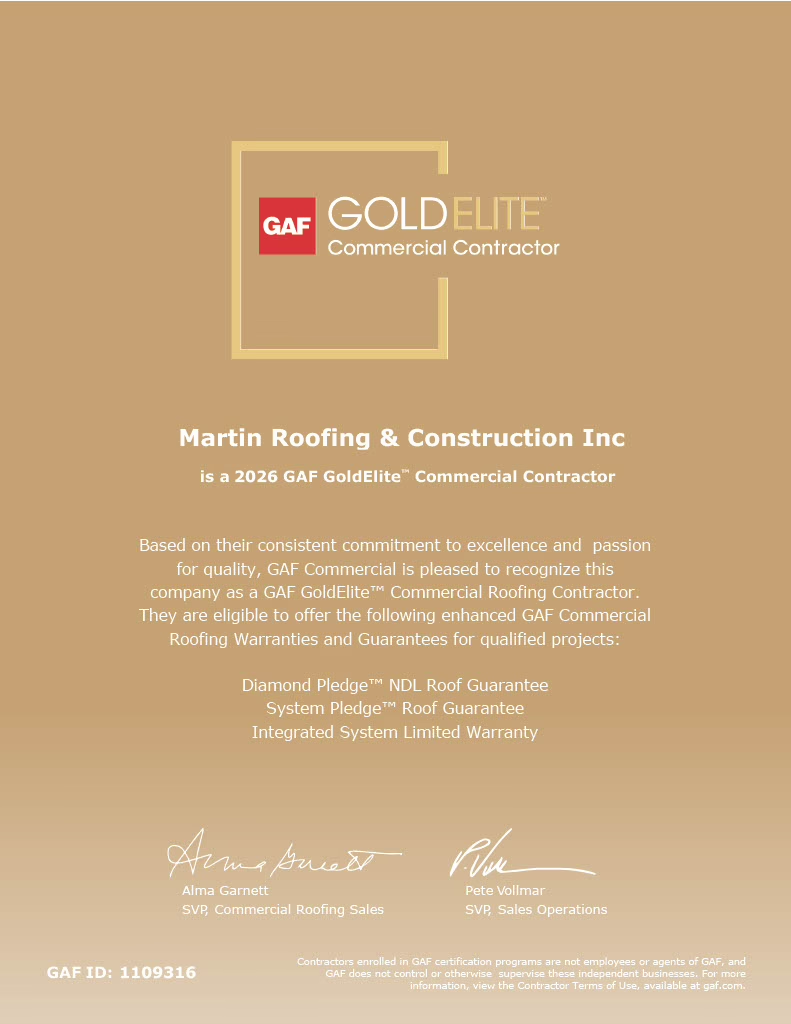

As a Service-Disabled Veteran-Owned Small Business with extensive experience in government, private, and public sector projects, Martin Roofing & Construction brings unique qualifications to commercial modified bitumen installations.

Proven Track Record

With years of experience installing modified bitumen systems throughout Bucks County and Montgomery County, Martin Roofing & Construction has the expertise to handle projects of any size and complexity.

Quality Materials and Partnerships

Working with leading manufacturers like Firestone, GAF, and other industry leaders ensures that every installation uses proven materials backed by comprehensive warranties.

Comprehensive Service Approach

From initial assessment through installation and ongoing maintenance support, Martin Roofing & Construction provides complete commercial roofing solutions that protect your investment and support your business operations.

Making the Decision: Is Modified Bitumen Right for Your Property?

Choosing the right roofing system for your commercial property requires careful consideration of your specific needs, budget, and long-term plans. Modified bitumen offers compelling advantages for many commercial applications, but the decision should be based on professional evaluation of your particular situation.

Consider factors such as your building’s age and condition, local climate conditions, budget constraints, and long-term ownership plans. A professional evaluation from experienced contractors can help you understand how modified bitumen would perform on your specific building and whether it’s the best choice among available options.

The Bottom Line

Modified bitumen roofing has earned its reputation as a reliable, durable solution for commercial properties through decades of proven performance. Its combination of weather resistance, longevity, and maintainability makes it an excellent choice for property owners who want predictable performance and long-term value.

When properly installed by experienced professionals and maintained according to recommended protocols, modified bitumen systems provide the reliable protection that commercial buildings need while offering the economic advantages that property owners demand.

If you’re considering roofing options for your commercial property, modified bitumen deserves serious consideration. Its track record of success, combined with ongoing innovations in materials and installation techniques, continues to make it a smart choice for commercial property owners who want roofing systems they can count on for decades to come.

The investment in quality roofing pays dividends, not just in avoiding leaks and repairs, but in the peace of mind that comes from knowing your building is properly protected. Contact Martin Roofing & Construction today to secure yours today. In the world of commercial real estate, that peace of mind is invaluable, and modified bitumen roofing systems have been providing it to smart property owners for decades.